J-Sol Medical Tokyo Factory

A Manufacturing Hub in Central Tokyo with Integrated Headquarters Functions

Factory Overview (Located within Tokyo Headquarters)

Location: 2-5-16 Shimo-ochiai, Shinjuku-ku, Tokyo

- Marketing Authorization Holder for Medical Devices (Type 1)

- Medical Device Manufacturing

- Sales and Leasing of Specially Controlled Medical Devices

- Medical Device Repair

- Cosmetics Manufacturing / Marketing Authorization Holder

- Quasi-drug Manufacturing / Marketing Authorization Holder

- ISO 13485 Certified

Factory Functions & Roles

The Tokyo Factory serves as an in-house manufacturing facility capable of flexible product distribution. We have established a system to handle a wide range of tasks, from manufacturing self-developed OEM products and prototyping to contract manufacturing for certified domestic products.

We can handle everything from the initial stages of product development to mass production and certification acquirement by utilizing our above system. we can offer providing manufacturing support tailored to both internal and external needs in addition.

Integrated Production

System

Completion all process from product development to manufacturing in our Tokyo Headquarters and Factory, ensuring both speed and quality.

Adaptable to

Flexible Production

Adaptable to domestic production for both OEM and in-house products. Any consultation for prototyping and small-lot production.

Wide Range of Product

Categories

Capable of handling diverse products, including medical devices and quasi-drugs.

Features & Equipment

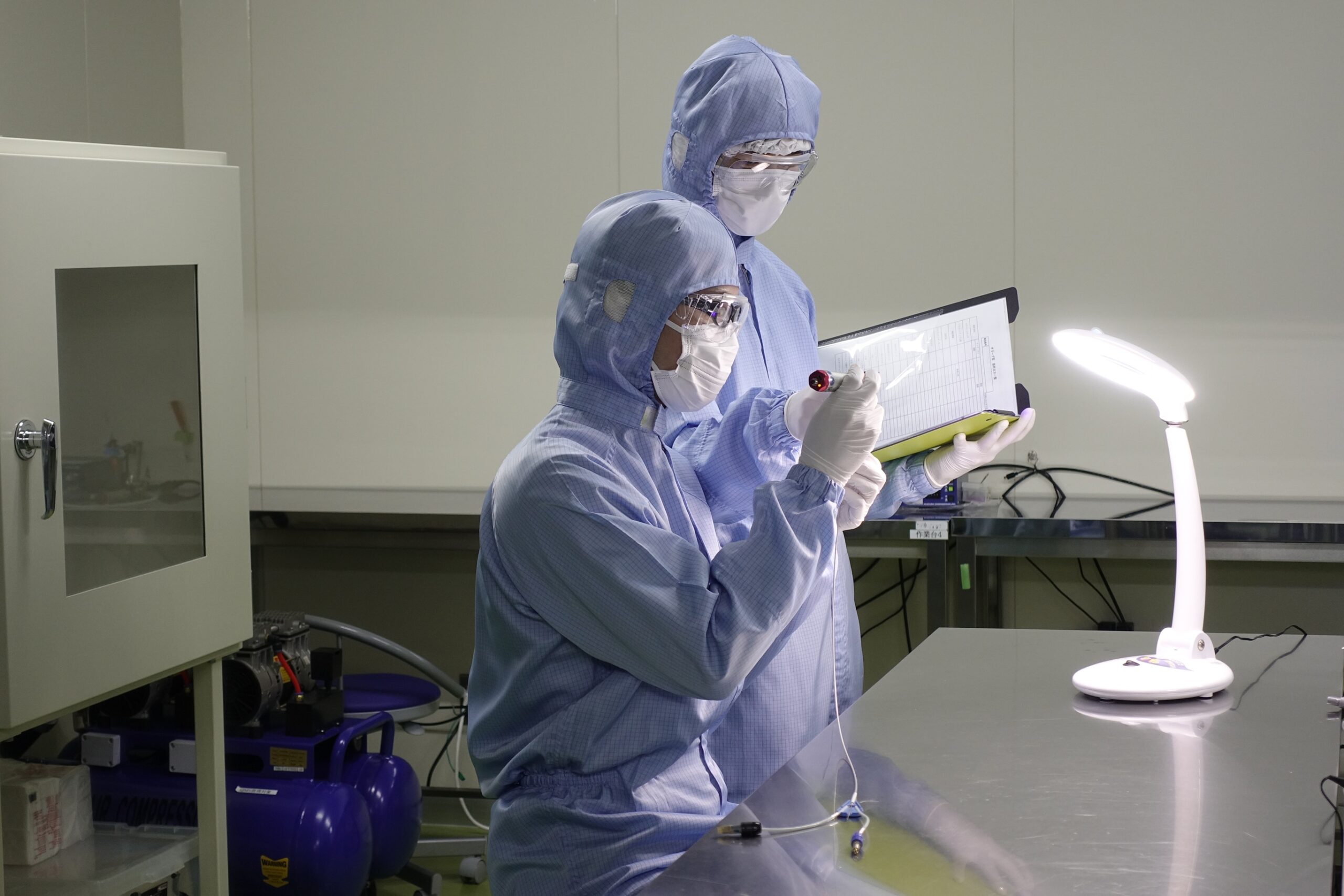

Class 100,000 Cleanroom

We established our in-house development and manufacturing department in 2015, introducing a cleanroom capable of manufacturing and inspecting particle-sensitive medical devices.

Sanitary Quality Inspection Environment

We maintain an inspection room with thorough hygiene management. Using visual checks, microscopes, magnifying glasses, and other optimal equipment, we conduct inspections according to product requirements. We also perform inspections for minute foreign matter, capable of distinguishing particles as small as 0.08 mm².

Domestic Final Product Storage Warehouse

Located in the city center, the Tokyo Headquarters Factory functions not only as a manufacturing site for self-developed products but also as a “Domestic Final Product Storage” facility for imported medical devices. We have established a safe and secure storage system, including temperature and humidity control, and have a proven track record of handling a wide variety of products.

Qualified Personnel at the Factory

Medical Device Responsible Engineering Manager

In addition to manufacturing in-house developed products, the Tokyo Factory is responsible for the domestic storage of final products for multiple imported medical devices. To ensure the quality and safety required for medical device manufacturing, we strive daily to strengthen product quality control, regulatory compliance, and hygiene management systems.

Working Environment Measurement Expert

Based on the Industrial Safety and Health Act and the Working Environment Measurement Act, we measure and analyze harmful factors in the workplace environment, striving to maintain hygiene and safety. Based on measurement results, we consider equipment improvements and reviews of work methods to build a better working environment.

Quality Assurance Structure through Manufacturing and Sales Collaboration

Commitment to Safety and Quality

Our headquarters holds the Marketing Authorization for Medical Devices and ensures product quality, safety, and regulatory compliance through close cooperation with the manufacturing site. Through information sharing with manufacturers and audits of manufacturing processes, we have built a system for product traceability and stable supply.

ISO 13485 Certification

We have obtained ISO 13485 certification, the international standard for medical device quality management systems, and operate a quality assurance structure based on these global standards.

With our systems for safety, efficacy, and regulatory compliance backed by third-party certification, we are able to provide products that medical institutions and patients can use with greater peace of mind.

Message from Responsible Officers (Marketing Authorization Holder)

General Marketing Compliance Officer

To strictly enforce regulatory compliance, quality control, and safety management, I work in collaboration with the Domestic Quality Administration Manager and the Safety Management Supervisor. We are building a system where every employee takes responsibility for quality and is conscious of improvement. Our mission is to deliver safe, high-quality products to the market so that medical professionals and patients can use our devices with confidence.

Domestic Quality Administration Manager

Our company handles both in-house manufactured goods and imported products, requiring a diverse range of quality control measures. Leveraging over 10 years of practical experience, I strive to maintain strict quality standards and pursue continuous improvement.

I am committed to diligent quality management every day to deliver “peace of mind” and “smiles” to patients and medical professionals through our products.

Safety Management Supervisor

We continuously monitor product safety by collecting and examining safety management information for medical devices. With the mission of providing safe and reliable medical devices that support everyone’s health, we will continue to work as a united team on product safety management.